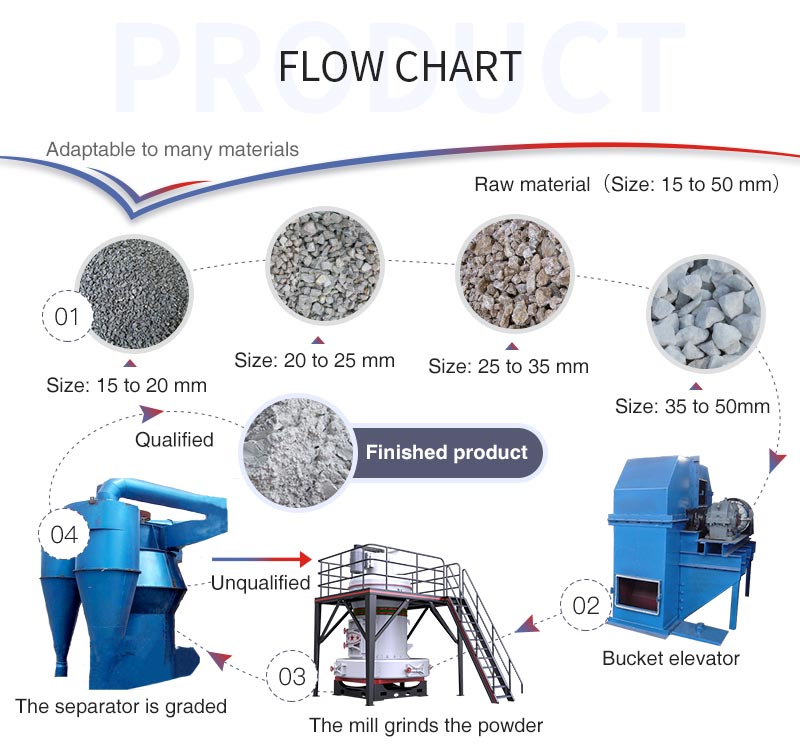

Application materials: limestone, calcite, calcium carbonate, dolomite, barite, talc, gypsum, diabase, quartz, bentonite, etc.

The machine is suitable for conducting high-fine powder processing of non-flammable and explosive materials, such as barite, limestone, and slag with a Mohs hardness of not more than 9.3 and a humidity of less than 6%.

Production capacity

8-176 t/dFeeding size

≤30mm

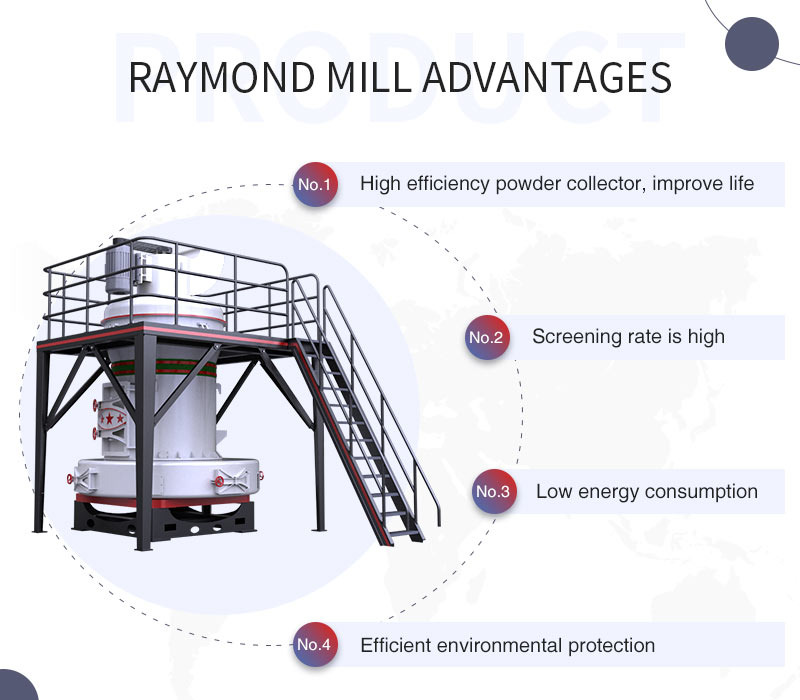

Raymond mill is also called grinding mill, Raymond machine, high efficiency grinding mill, suspension roller mill. This equipment is based on the research and development of grinding equipment for more than 20 years. Absorbing the latest grinding technology and concept at home and abroad, we have developed such a new product with international leading technology level. The device is more efficient than the ball mill, low power consumption, small installation area, and low investment for one time.

A Raymond mill is widely applied to finely grind more than 280 non-flammable and explosive materials, whose Moh's hardness is less than 9.3 and humidity is below 6%,such as barite, calcite, potassium feldspar, talc, marble, limestone, dolomite, fluorite, lime, activated clay, activated carbon, bentonite, kaolin, cement, phosphate ore, gypsum, glass, insulation materials, etc. It can be used in many industries, such as chemical engineering, construction, etc. Its final product’s particle size can be adjusted at random within the 80-325 mesh.

We can provide program design, process flow design, standard and non-standard design and production lines for clients.

If you have any questions, such as the price, the service life of the machine, after-sales service, etc, please contact customer service or send an email at info@hxjq.com

| Parameter Model |

Raymond mill62 | High strength66 | High strength76 | High strength87 | High strength92 | High strength93 | High strength97 | Raymond mill4119 | Raymond mill4525 |

| Feeding size(mm) |

<15 | <15 | <20 | <25 | <25 | <25 | <25 | ≤25 | ≤30 |

| Size of finished product(mm) |

0.173-0.033 | 0.173-0.033 | 0.173-0.033 | 0.173-0.033 | 0.173-0.033 | 0.173-0.033 | 0.173-0.033 | 0.173-0.044 | 0.173-0.044 |

| Shift output of different material fineness(t) |

0.6-9 | 1-20 | 1.5-25 | 2.8-33 | 3-36 | 3.5-40 | 4-52 | 8-78 | 16-176 |

| Rotate speed of central shart(r/min) |

274 | 190 | 170 | 161 | 148 | 140 | 130 | 105 | 82 |

| Diameter of pulverizing ring(mm) |

525 | 725 | 850 | 907.5 | 973 | 1006 | 1050 | 1400 | 1770 |

| Diameter of pulverizing ring(mm) |

150 | 210 | 250 | 270 | 300 | 300 | 310 | 410 | 450 |

| Height of pulverizing roller(mm) |

100 | 150 | 150 | 150 | 160 | 160 | 170 | 190 | 250 |

| Main Motor(kw) | 7.5 | 15 | 18.5 | 22 | 30 | 30 | 37 | 75 | 132 |

| Fan Motor | 4-5.5 | 4-11 | 4-15 | 4-18.5 | 4-22 | 2-22 | 4-37 | 4-75 | 4-132 |

| Analyzer Motor | 6-1.1 | 6-2.2 | 6-2.2 | 6-2.2 | 6-2.2 | 6-3 | 4A-5.5 | 4B-7.5 | 4A-18.5 |

Henan Hongxing Mining Machinery Co., Ltd. (HXJQ) covers an area of 350,000 square meters which includes 260,000 square meters of heavy duty industrial workshops.

Please tell us your needs like expected capacity, we have professional engineers to customize the proper production process for you.