Applied materials: light calcium carbonate, graphite, inorganic mud, lime slurry, ore mud, phosphate slag, dregs, pomace, aquatic product waste, etc.

The rotary dryer is a common drying equipment. It has a wide operating range, strong practicability, and large processing range. The equipment is mainly used in metallurgy, building materials, chemical industry, coal washing, fertilizer, ore, etc.

Production capacity

1.9-76t/hShell cubage

9.0-285m³

The dryer is also called a rotary dryer for drying materials with certain humidity and granularity, such as materials coming out of a ball mill. The equipment is reliable in operation, flexible in operation, adaptable and capable of processing. It is widely used in metallurgy, building materials, chemical industry, coal washing, fertilizer, ore, sand, clay, kaolin, and other fields. The dryer belongs to the industrial dryer equipment.

1. Rotary Drum Dryer: ores, slag(blast furnace slag for cement industry), coal/coal slime, metal powder, clay, kaolin, bentonite, sawdust, river sand, coal ash.

2. Sand Dryer:river sand, sea sand,garnet sand,carborundum,silica sand,quartz sand, zircon sand.

3. Mineral Powder Dryer: metallic and non-metallic minerals powder

Metallic mineral powder: copper ore powder, iron ore powder, alumina powder, mercury ore powder, tin ore powder, cobalt powder, nickel powder, manganese ore powder, gold ore powder, hematite powder.

Non-metallic mineral powder: talc powder, calcium carbonate powder, kaolin, quartz, silica lime powder, limestone powder, dolomite powder, calcite powder, etc

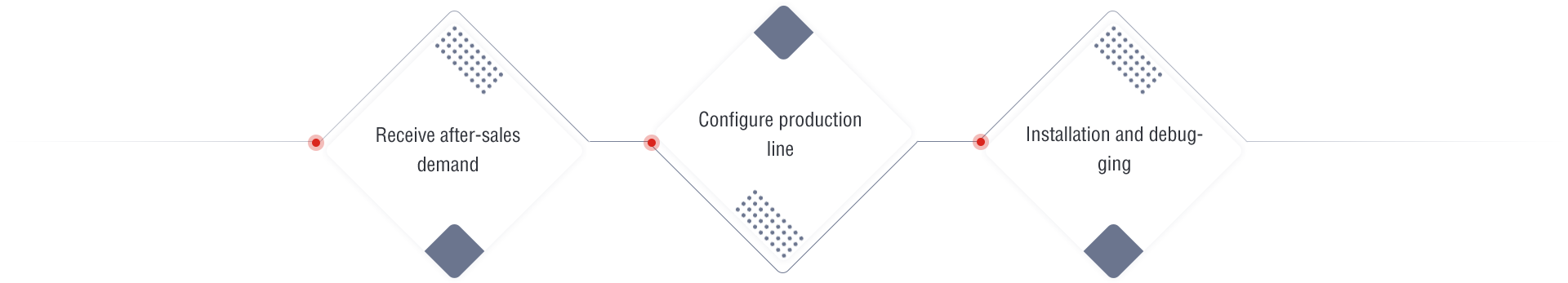

We can provide program design, process flow design, standard and non-standard design and production lines for clients.

If you want to know more, such as dryer investment and returns, advantages, costs, fuel consumption, main heat sources, etc, please contact us or send an email at info@hxjq.com

|

Spec./m

(Dia.×Length) |

Shell Cubage

(m³) |

Capacity

(t/h) |

Installation

Obliquity (%) |

Highest Inlet

Air Temperature (℃) |

Main Motor

(kw) |

Weight

(t) |

|

Φ1.2×8.0

|

9.0

|

1.9~2.4

|

3~5

|

700~800

|

7.5

|

9

|

|

Φ1.2×10

|

11.3

|

2.4~3.0

|

3~5

|

700~800

|

7.5

|

11

|

|

Φ1.5×12

|

21.2

|

4.5~5.7

|

3~5

|

700~800

|

15

|

18.5

|

|

Φ1.5×14

|

24.7

|

5.3~6.6

|

3~5

|

700~800

|

15

|

19.7

|

|

Φ1.5×15

|

26.5

|

5.7~7.1

|

3~5

|

700~800

|

15

|

20.5

|

|

Φ1.8×12

|

30.5

|

6.5~8.1

|

3~5

|

700~800

|

18.5

|

21.5

|

|

Φ1.8×14

|

35.6

|

7.6~9.5

|

3~5

|

700~800

|

18.5

|

23

|

|

Φ2.2×12

|

45.6

|

9.7~12.2

|

3~5

|

700~800

|

22

|

33.5

|

|

Φ2.2×14

|

53.2

|

11.4~14.2

|

3~5

|

700~800

|

22

|

36

|

|

Φ2.2×16

|

60.8

|

13.0~16.2

|

3~5

|

700~800

|

22

|

38

|

|

Φ2.4×14

|

63.3

|

13.5~16.9

|

3~5

|

700~800

|

37

|

45

|

|

Φ2.4×18

|

81.4

|

17.4~21.7

|

3~5

|

700~800

|

37

|

49

|

|

Φ2.4×20

|

90.4

|

19.3~24.1

|

3~5

|

700~800

|

45

|

54

|

|

Φ2.4×22

|

99.5

|

21.2~26.5

|

3~5

|

700~800

|

45

|

58

|

|

Φ2.6×24

|

127.4

|

27.2~34.0

|

3~5

|

700~800

|

55

|

73

|

|

Φ3.0×20

|

141.3

|

30.1~37.7

|

3~5

|

700~800

|

75

|

85

|

|

Φ3.0×25

|

176.6

|

37.7~47.1

|

3~5

|

700~800

|

75

|

95

|

|

Φ3.2×25

|

201

|

42.9~53.6

|

3~5

|

700~800

|

90

|

110

|

|

Φ3.6×28

|

285

|

60.8~76.0

|

3~5

|

700~800

|

160

|

135

|

Technical parameters of indirect heat dryer:

| Shell diameter ×shell Length Items |

Inside diameter of outer shell (mm) |

Inside diameter of inner shell (mm) |

Shell Length (m) |

Shell cubage (m³) |

Shell obliquity |

Lifting blade form |

Highest inlet air temperature (℃) |

Dimensions (m) |

| Φ1.5×15m | 1500 | 500 | 15 | 20.27 | 3-5% | Lifting form | 850 | 16.2×2.7×2.7 |

| Φ1.5×17m | 17 | 22.97 | 18.2×2.7×2.7 | |||||

| Φ1.5×19m | 19 | 25.68 | 20.0×2.9×2.9 | |||||

| Φ1.8×21m | 1800 | 650 | 21 | 35.91 | 3-5% | Lifting form | 850 | 22.5×2.7×2.7 |

| Φ1.8×23m | 23 | 39.33 | 24.5×2.9×2.9 | |||||

| Φ1.8×25m | 25 | 42.75 | 26.5×2.9×2.9 | |||||

| Φ2.2×21m | 2200 | 800 | 21 | 58.10 | 3-5% | Lifting form | 850 | ---- |

| Φ2.2×23m | 23 | 63.61 | ||||||

| Φ2.2×25m | 25 | 69.15 |

Henan Hongxing Mining Machinery Co., Ltd. (HXJQ) covers an area of 350,000 square meters which includes 260,000 square meters of heavy duty industrial workshops.

Please tell us your needs like expected capacity, we have professional engineers to customize the proper production process for you.